The Anatomy of a Turnbull & Asser Shirt

"A shirt," says Steven Quin, Turnbull & Asser’s Royal Warrant holder and Bespoke Director, "is not just a shirt. There’s a certain philosophy behind it that makes it what it is: the people, the skill, the approach, the cloth. You can feel it. It’s more than just high quality, it’s about maintaining that quality consistently, year after year. Shirts, after all, are our business."

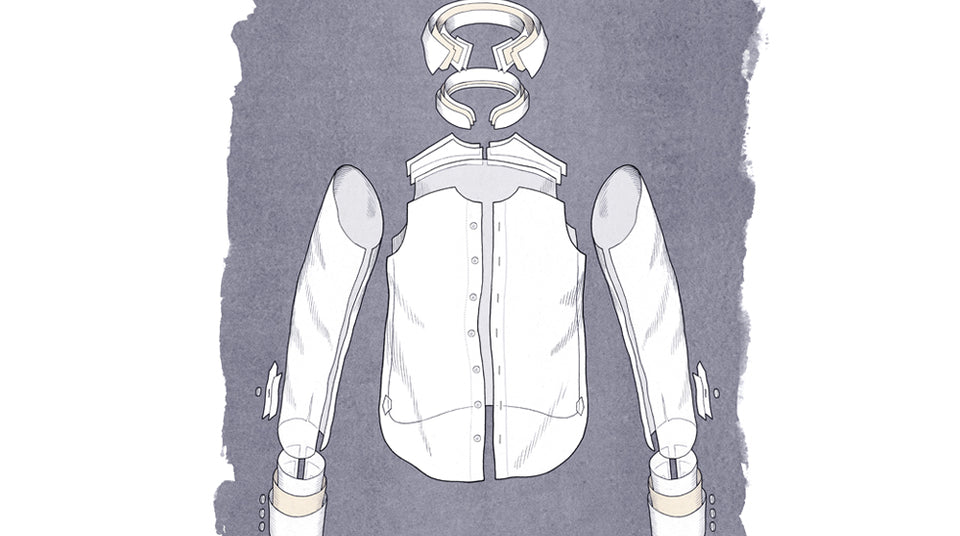

Indeed, look more closely at the details that make for a ready-to-wear Turnbull & Asser business shirt, look more closely at any of the 33 various components of which it comprises, and, given the right insights, that becomes apparent.

Take, for example, the collar – that part of a shirt, which is always visible. Yes, there’s that certain, slightly rounded style to a Turnbull & Asser collar that allows it to sit just so over the collar bone – a curve that’s easy to achieve on a mannequin but is much more difficult to get to work to on a real human. But go deeper and one notices that, while other shirts are made with a fused collar – which is to say its parts are glued together – here they are what is known as loose-lined: its major parts can move freely over each other.

The Regent collar offers a medium spread with a higher stance, while the classic Turnbull & Asser collar has a deep point and outward flare.

‘That’s not just harder to make for its own sake,’ Quin stresses. ‘It gives more life and character to the collar, looks as good worn open-necked as done up and, since glues tend to degrade natural fibres over time, it also makes the collar longer-lasting and more comfortable.’

Or look to the shirt’s yoke – the part covering the shoulders to the rear of the collar. It’s made with a split, in two parts, long regarded as a sign of a quality shirt, yet easily replicated on a mass-production version. What makes Turnbull & Asser’s different is that the cloth used is hand-cut on the bias – at a slight angle – which adds more give, and thus more comfort across the shoulders too.

‘It’s just another little detail – like the fact that all of our ready-to-wear shirts come with either double, cocktail or three-button cuffs – that have been signature styles for more than a half a century. A three-button cuff may sound excessive, but it allows the wearing of a bigger watch, for example, and will probably be around long after the fashion for big watches has gone. It’s those details that make wearing a Turnbull & Asser shirt like being in a club. We wouldn’t put a logo on our shirts but people who wear our shirts know each other from those little touches.’

The double cuff and the three-button cuff.

Those touches are what comes out of an exacting construction process, the details of which are often exclusive to Turnbull & Asser. Once the cutting of the cloth is done, it goes to the sewing room for specialists to work on each element of the shirt. First the placket is shaped on the front of the shirt – a one and one-quarter inch placket, or ‘front hem’ as they call it in the trade, that’s not a separate component sewn onto the shirt, but which is made from the body of the shirt, thus giving it a greater integral strength; the placket is also both lightly lined and raised for a crisper finish and all-round better presentation for the shirt. Next the yoke is attached to its back. The left and right front sections of the shirt are then attached to create its basic scaffolding, to which the collar and cuffs will be added.

By the time the sleeves are sewn on – using an unusually deep hem for extra durability – the cuffs have already been attached: this is done using a distinctive gathering of the sleeve fabric into the cuff, rather than by the use of pleats, which both distributes the cloth more evenly and makes ironing easier. The shirt is then hemmed, with a curve, which gives more tolerance to the fabric and so helps the shirt stay tucked in. The collar is then attached – another process handled by a dedicated machinist.

'We’re not the only people making shirts. The difference is that we make them with excellence.'

The last process, also carried out by specialists, is the addition of button holes and buttons. The shirt then passes to a quality control team and then to pressing, ready for packaging; a second quality control inspection sees it passed back if even the slightest aberration from the high standards set is noticed. Once passed, the shirt is ready to be sold to wearers who appreciate all the signature details: the likes of the neat white gussets at the base of those double-stitched side seams, or that just-so approach to stitching.

Indeed, while many mistake the number of stitches per inch as some golden indicator of shirting quality – Turnbull & Asser sews with some 18-20 single needle stitches per inch – ‘still you can have too many stitches and it looks awful,’ Quin explains. ‘What matters is the right number of stitches sewn with consistency. That’s the tricky part.

That’s what we pull off with shirt after shirt. We’re not the only people making shirts. The difference is that we make them with excellence.’ And in many varieties too, some, says Quin, dictated by broad trends that Turnbull & Asser identifies as interesting to pursue, while others are the bedrock of the brand’s offer. Of course, by far the most typical shirt from the company is the classic business variety, with that ‘stiff upper lip’ collar, as Quin calls it. It looks fantastic with a tie, he says, but – importantly in a market in which men typically want their shirts to be ‘dual use’ – also looks good worn open-collared with a pair of chinos at the weekend.

But, of course, while it also makes dress shirts – for that black tie event – Turnbull & Asser appreciates that shirts aren’t just for wearing under a suit, and its range recognises the fact. Those who really want to signal that they’re not at work might, for example, opt for a button-down collar shirt. This is the archetypal casual shirt – teaming well with jeans for a more American style, in fact – adaptable to different fabrics, so works just as well in a linen as a poplin. Turnbull & Asser’s Cambridge collar – a smaller, button-through collar style – brings a more contemporary spin.

If a cooler climate requires it, the company makes shirts in a cotton and cashmere blend. But if it’s heat that’s the more appealing problem, as part of the bespoke service there’s the short or half-sleeve shirt, again in multiple fabrics, depending on whether it’s being worn to the office or on holiday. Cut is important here: a looser fit ensures that the shirt hangs slightly away from the body, helping you to stay cool. Occasionally the greater flexibility in design that a much less formal style of shirt like this allows for some entertaining departures from the norm: the likes of the camp or resort shirt, for example, with its easy, sit-down collar and in a bolder, more summery print.

This shirt is cut to look as good untucked as tucked in, so it can be worn with shorts. Variety is what any working wardrobe is about. Quin wears a classic Turnbull & Asser shirt to work everyday. But it’s trouble if he tries to wear one at the weekend. ‘Then I have to switch over to something more casual,’ he says. ‘My kids have their own Turnbull & Asser shirts – ones I’ve handed down to them – and they really like them. But there’s no way they’re going to let me wear a dress shirt at the weekend, Turnbull & Asser or not.’

Whatever the style, using high quality, long staple cotton cloths adds to the distinction of a Turnbull & Asser shirt too. While it is one of a very few makers whose shirts are all made in the UK – currently in Gloucester, and before that in Walthamstow – the demise of British mills over the last half century means that those characteristically colourful cloths come from Italy, notably the esteemed Albini mill. In fact it was a condition of Turnbull & Asser working with Albini that they re-create that certain substance that English cloths have – and that isn’t found in Italian shirt making.

‘We use all kinds of cloths for different kinds of shirts, from practical, mid-weight two-fold 120s up to the best in West Indian Sea Island cloth. That won’t last as long, but you might enjoy it more while it lasts,’ jokes Quin. Not that a Turnbull & Asser shirt won’t come in a cloth of distinction either way. ‘Our relationship with the Italian mills is long-standing and trusted, which means we can ask them to make certain colours and patterns especially for us – you can sometimes tell a Turnbull & Asser shirt not just by the way the pattern in the fabric is carefully matched between the shirt’s various components, but by the choice of fabric alone,’ says Quin. Often Turnbull & Asser will order a limited run of cloth, enough to make just 60 shirts.

‘But the fact is that while our shirts may have all the great ingredients – that strong thread, those polished sustainable Australian mother-of-pearl buttons and so on – if you don’t have great chefs too, those ingredients won’t make much difference,’ he says. ‘It’s the human element that gives the shirt its longevity but, just as importantly, also its personality. It’s a very English character – robust but refined, solid and reliable, but also comfortable.’ Quin stresses that it takes multiple people, each with their own specialist skill set – cutter, collar-maker, someone who cross lock-stitches on the buttons or shapes the button holes – to bring a Turnbull & Asser shirt together. ‘That’s why we cherish the kind of craft skills here that get passed down through the generations,’ he says. ‘Even if a lot of our experts could make an entire shirt, when we spot a certain talent for a certain operation, we focus their attention on that work. Frankly, it’s hard to find the people with the patience and ability to do this work now – they’re often people who were taught to sew as children, even if now they have to use very high-spec machinery. And that can be like a runaway locomotive if you don’t know how to handle it.’

The craftsmanship and rare timelessness of a Turnbull & Asser shirt means that one can be bought vintage, laundered and is good to wear now. That’s what makes the brand’s shirts less for the general consumer as for the kind of considered person willing to invest money in return for longevity and perhaps the chance to pass the shirts on to the next generation. It’s this that has convinced heads of state, captains of industry, moguls and maharajahs to wear Turnbull & Asser since the late 19th century – and which has seen the Prince of Wales bestow his Royal Warrant on Turnbull & Asser shirts, ‘more or less since he started wearing shirts,’ says Quin. ‘We’re very proud to have that Royal Warrant. It’s a stamp of approval and, since our competition is international, having the Prince of Wales’ crest in our shirts certainly lends them a gravitas abroad – you’re wearing a little piece of England on your back.’ And that’s as good a definition for a Turnbull & Asser shirt as any.